In the world of heavy lifting, choosing the right Lifting Sling is crucial. Various types of slings exist, each designed for specific tasks. Picking an inappropriate sling can lead to accidents or inefficiencies.

Lifting Slings come in several designs. Some are made of synthetic materials, while others are metal. The choice often depends on the load and environment. For instance, web slings are lightweight and versatile. Chain slings, however, offer strength and durability in rough conditions. Not every option fits every lift. It's essential to assess the factors in play.

Reflecting on the use of Lifting Slings is important. With varying materials and designs, there can be confusion. Misjudgments in selection can lead to problems on-site. The goal should be safety and effectiveness. A deeper understanding of each type helps avoid potential mishaps. Making informed choices can improve overall workplace safety and efficiency.

Lifting slings come in various types, each made from different materials. Understanding these materials is crucial for selecting the right sling for specific tasks. Common materials include nylon, polyester, and wire rope.

Nylon slings are known for their strength and flexibility. They can stretch under load, absorbing shock, which makes them suitable for dynamic lifting operations. However, they can be affected by UV light and chemicals, which may weaken the material over time. A study from the Lifting Equipment Engineers Association noted that nylon slings can handle loads up to 8,000 pounds, but their lifespan can vary greatly depending on usage and maintenance.

Polyester slings are popular due to their resistance to abrasion and UV rays. They're less stretchy than nylon, which provides more stability during lifting. However, if exposed to extreme heat, polyester can lose its strength. According to a report from the American Society of Mechanical Engineers, these slings often have a load capacity between 6,000 to 12,000 pounds, depending on their design.

Wire rope slings are made for heavy-duty tasks. They offer unparalleled strength and durability. Yet, their rigidity can lead to handling challenges. A study by the International Association of Drilling Contractors suggests that wire rope slings can bear loads exceeding 28,000 pounds. Ensuring proper inspection and maintenance is vital to prevent failures. Understanding the limitations and characteristics of each material helps ensure safety in lifting operations.

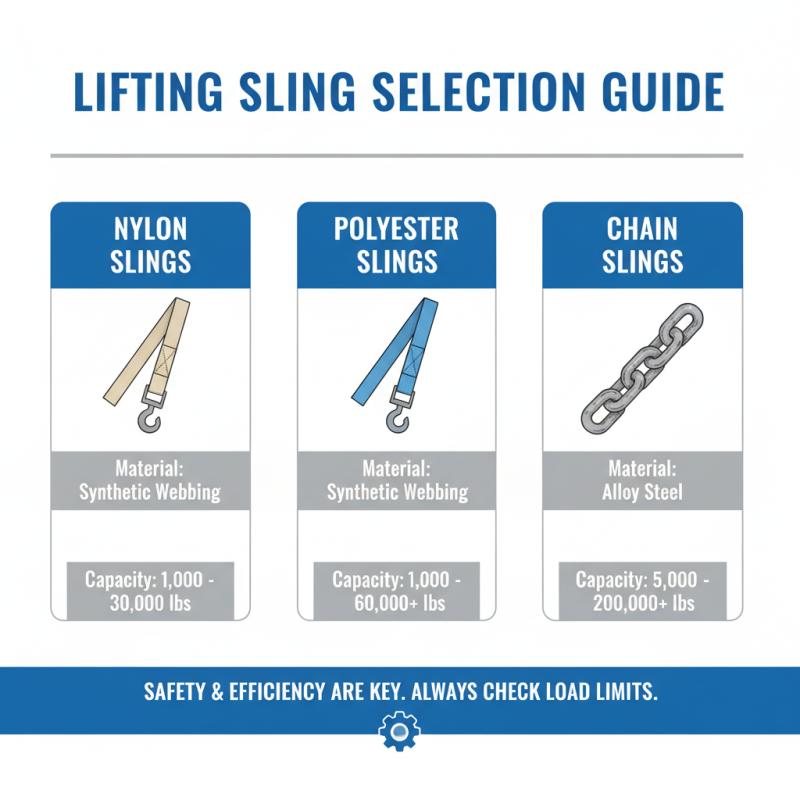

This chart illustrates the various types of lifting slings and their respective load capacities (in tons). Understanding the strengths of each type helps in choosing the right sling for specific lifting tasks.

Selecting the right lifting sling is crucial for safety and efficiency. The weight capacity of a lifting sling plays a significant role in your choice. According to industry reports, slings come in various materials like nylon, polyester, and chain. Each material has a specific weight limit that you must consider. For example, polyester slings can typically handle loads between 1,000 to over 60,000 pounds, depending on their width and length.

Understanding the weight capacity of each sling type can help you avoid accidents. Overloading slings could lead to failures. It's important to consult manufacturers' guidelines to ascertain the limits. Always account for the lifting angle, as this affects the effective weight that your sling can handle.

Tips: Regular inspections are vital. Check for wear and tear. Always use slings that meet the required lifting capacity for your specific job. Lastly, training operators on proper sling use can prevent mishaps. This attention to detail is imperative in maintaining safety standards in lifting operations.

Synthetic slings have gained popularity across various industries due to their versatility. Constructed from high-strength fibers, these slings weigh less and are easier to handle. They can lift heavy loads without the bulk of steel cables. However, there are specific considerations when choosing synthetic slings for different applications.

In the construction industry, synthetic slings excel in lifting equipment and materials. Their lighter weight means less strain on workers. Plus, they resist abrasion, which is crucial on job sites. However, they can degrade from sunlight exposure, requiring regular inspections. In contrast, the aerospace sector often uses synthetic slings for delicate components. These slings provide a stable grip, minimizing the risk of damage. Yet, the high costs associated with these slings can be a barrier for some companies.

The manufacturing sector also benefits from synthetic slings. They are ideal for assembly lines and transport of goods. Their flexibility accommodates various load shapes. Unfortunately, improper use can lead to accidents. Workers must be trained on safe practices. Additionally, issues like knotting or tangling can occur if not managed well.

| Lifting Sling Type | Material | Best Uses | Safety Features |

|---|---|---|---|

| Polyester Sling | Synthetic Fiber | Construction, Warehousing | UV Resistant, Color Coded |

| Chain Sling | Steel | Heavy Machinery, Metal Fabrication | High Strength, Heat Resistant |

| Wire Rope Sling | Steel Wire | Oil & Gas, Marine | Rust and Corrosion Resistant |

| Round Sling | Polyester | Automotive, Manufacturing | Soft and Flexible |

| Web Sling | Nylon/Polyester | General Purpose | Lightweight, Easy to Handle |

When it comes to heavy lifting, the choice of sling matters greatly.

Chain slings offer durability and strength.

They can handle heavy loads with ease. Their design allows them to be flexible in various lifting situations.

Chain slings work well in environments where sharp edges are present. However, they can be heavy and cumbersome.

This might make them less ideal for quick setups.

Wire rope slings, on the other hand, are lightweight and easy to manipulate.

They are resistant to abrasion and fatigue. This makes them suitable for many applications. Yet, wire slings can be more prone to fraying and damage over time.

Regular inspections are essential. The challenge lies in balancing strength and ease of use.

Users must assess specific lifting needs before making a choice.

Understanding the differences between these slings is crucial. Each has its strengths and weaknesses.

Organizations must weigh the factors carefully. Not all lifting situations are the same. Choosing the right sling can mean the difference between

success and failure on the job site.

When using lifting slings, safety is paramount. Reports indicate that improper use of slings contributes to 30% of lifting-related accidents in industrial settings. Training operators on proper techniques is essential. Slings should only be used as intended. Operators must be aware of the load capacity and conditions.

Regular inspections are critical. Wear and tear can compromise sling integrity. Data shows that 25% of accidents involve slings that were not inspected before use. Color codes and tags specify load limits and guidelines. Each sling type requires different handling. For example, chain slings offer high capacity but may be heavier than web slings.

It is vital to check for proper rigging angles. Angles outside the recommended range can increase load stress. Mistakes here are common, leading to accidents. The industry needs to focus on education. Many workers express uncertainty about sling safety. Identifying and addressing gaps in knowledge could reduce risks significantly.