In the realm of cargo transportation, ensuring the safety and security of your load is paramount. One of the most effective tools for achieving this is the ratchet strap. These versatile and robust fastening devices are designed to securely hold various types of cargo during transit, preventing unwanted movement and potential damage. As you embark on your journey, whether for personal use or professional shipping, understanding the importance and functionality of ratchet straps can make all the difference.

Choosing the right ratchet straps can be a daunting task, given the myriad of options available on the market. Factors such as load capacity, strap length, and material strength can influence your selection process. This guide will highlight the ten best ratchet straps, delving into their features and benefits, ensuring you have the information necessary to make an informed decision. With the right ratchet straps, you can transport your goods with confidence, knowing they are securely fastened and protected throughout the journey.

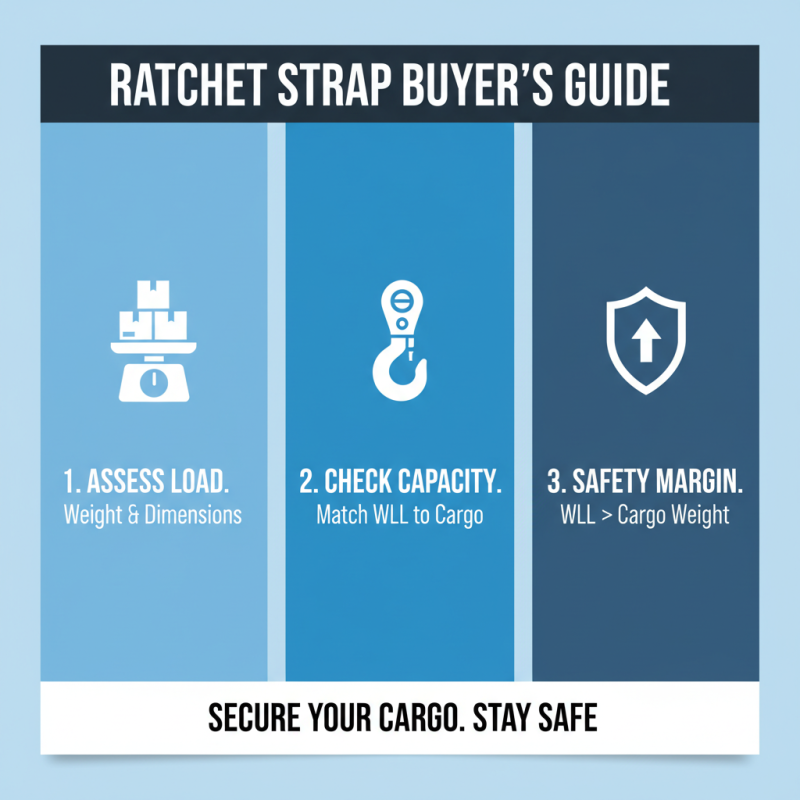

When choosing ratchet straps for cargo safety, several key considerations should guide your selection process. First and foremost, it's crucial to assess the weight and dimensions of the load you plan to transport. Ratchet straps come in various weight capacities, so ensuring that the straps can handle the specific load is essential for safe transportation. Choosing straps with a higher working load limit than your cargo's weight will provide an extra margin of safety and help prevent accidents during transit.

Material and construction are also important factors to consider. Look for ratchet straps made from durable fabrics, such as polyester, which offer strength and resistance to wear and tear. Additionally, pay attention to the hardware components, including the ratchet mechanism and hooks. High-quality metal components will enhance the overall reliability of the straps and reduce the risk of failure. Furthermore, features like protective padding can prevent damage to cargo and ensure that the straps remain securely fastened throughout transportation. By carefully evaluating these considerations, you can choose ratchet straps that ensure your cargo remains secure and safe during transit.

When it comes to the safe transportation of cargo, the strength and durability of ratchet straps are paramount. These straps are designed to withstand significant tension while securely holding down loads. High-quality ratchet straps typically feature heavy-duty materials that resist wear and tear, including reinforced stitching and UV-resistant properties, ensuring longevity even under harsh environmental conditions. This durability not only enhances the lifespan of the straps but also contributes to their overall reliability during transport.

Another key feature that distinguishes top-tier ratchet straps is their load capacity, often indicated by a safe working load limit (WLL). It's essential that users select straps that exceed the expected weight of their cargo to prevent slippage or breakage during transit. Moreover, some ratchet straps come equipped with additional safety features, such as padded ratchet handles for improved grip and ease of operation, as well as protective sleeves to guard against abrasion. By focusing on these attributes, one can ensure that cargo remains safe and secure during transportation, reducing the risk of damage and enhancing the efficiency of logistics operations.

When it comes to securing cargo, understanding load limits and weight ratings is crucial for ensuring safety and efficiency during transportation. Every ratchet strap or cargo net comes with a specified weight rating, which indicates the maximum load it can safely handle. Overloading a strap beyond its designated weight limit not only compromises the integrity of the cargo being transported but also poses significant risks to road safety. Inadequate securing methods can lead to cargo shifting or even falling, causing accidents and injuries.

It is essential to evaluate the weight of the items being transported and choose ratchet straps or cargo nets that exceed the total weight to provide a margin of safety. Additionally, factors such as the distribution of weight and handling conditions should be carefully considered. Utilizing straps that securely lock while accommodating the load's dynamics helps avoid sudden shifts and ensures that items remain in place during transit. By prioritizing knowledge of weight ratings and adhering to recommended limits, cargo handlers can safeguard their loads while contributing to safer roadways for everyone.

This bar chart illustrates the weight ratings of various sizes of ratchet straps. Knowing the weight limits of each strap is crucial for safe cargo transportation, helping ensure your loads remain secure during transit.

When selecting ratchet straps for safe and secure cargo transportation, the choice of material plays a pivotal role in determining the strength and durability of the straps. Two of the most commonly used materials are nylon and polyester, each with distinct properties that cater to different transportation needs. According to the American Society for Testing and Materials (ASTM), polyester straps are known for their superior resistance to UV rays and moisture, making them ideal for outdoor use where exposure to environmental elements is a concern. In contrast, nylon straps offer increased stretch and elasticity, which can be beneficial in applications where a little give in the strap can help secure loads without damage.

A recent industry report highlighted that polyester ratchet straps generally exhibit lower stretch than nylon, which translates to better load stability during transport. This feature is particularly crucial for securing heavy cargo, where even minimal slack can result in load shifting and potential accidents. Statistical data indicates that approximately 75% of cargo-related accidents stem from improper securing methods or equipment failure, emphasizing the need for high-quality materials. Thus, choosing the right ratchet strap, based on material characteristics, can significantly enhance both safety and efficiency in cargo transport, ensuring that loads reach their destination securely.

When transporting cargo, ensuring that it remains secure is paramount to safe transport. Proper use of ratchet straps plays a critical role in preventing shifting during transit. First, it is essential to select the right ratchet strap for your load. Consider the weight, size, and nature of the cargo. For heavier loads, opt for wider straps with higher break strengths to distribute tension evenly and reduce the risk of failure.

When securing the cargo, position the ratchet straps strategically to maximize their effectiveness. Ideally, straps should be placed at an angle of 45 degrees when possible, as this helps to create a more stable grip. Be careful not to overtighten, as excessive tension can damage both the cargo and the straps. After securing the load, conduct a final inspection to ensure that the straps are snug and that they grip without slack. Regularly check the straps throughout the journey, as vibrations and movements can cause them to loosen over time. Following these best practices will help maintain safety and security for your cargo during transportation.