Choosing the right webbing strap for your project can significantly influence the success and safety of your endeavors. According to Sarah Thompson, a leading expert in the webbing industry, "The key to a successful project is understanding the specific requirements of your applications and selecting webbing straps that meet those demands." This insight emphasizes the importance of identifying the appropriate type of webbing strap to ensure reliability and effectiveness in various usage contexts.

When embarking on a project that requires webbing straps, factors such as material, width, and load capacity must be carefully considered. Different projects may call for different types of straps, such as nylon for its strength and versatility, or polyester for its UV resistance and durability. Understanding the characteristics of various webbing straps is essential to choose the best fit for your specific needs.

In this guide, we will explore the essential criteria for selecting webbing straps, focusing on their applications and the benefits they offer. By leveraging expert insights and industry knowledge, you will be equipped to make informed decisions that enhance the performance and safety of your projects.

When selecting webbing straps for your project, it’s essential to understand the different types available, as each comes with unique properties tailored for specific applications. One of the most common types is nylon webbing, known for its strength and durability. This material is resistant to abrasion and mildew, making it ideal for outdoor uses such as camping equipment and harnesses. Additionally, nylon webbing maintains flexibility and does not become brittle over time, which ensures its longevity in various conditions.

Another popular option is polyester webbing. While slightly less elastic than nylon, polyester offers a higher level of UV resistance, making it an excellent choice for projects exposed to sunlight for prolonged periods. Its inherent properties allow it to hold its shape and strength, making it suitable for applications such as strapping, securing cargo, or even crafting into bags and belts. Understanding these materials helps in making an informed decision based on the specific demands of your project, including load capacity, moisture resistance, and environmental exposure.

| Type of Webbing Strap | Material | Strength (Breaking Force) | Common Uses | Width (inches) |

|---|---|---|---|---|

| Polyester Webbing | Polyester | 2,000 lbs | Outdoor gear, straps, and ties | 1, 2, 3 |

| Nylon Webbing | Nylon | 4,000 lbs | Seat belts, climbing gear | 1, 1.5, 2 |

| Cotton Webbing | Cotton | 600 lbs | Bags, fashion straps | 1, 2 |

| Polypropylene Webbing | Polypropylene | 1,500 lbs | Boating, marine applications | 1, 1.5, 2.5 |

| Heavy-Duty Webbing | Various Synthetic | 10,000 lbs | Industrial and commercial equipment | 2, 3 |

When selecting the right webbing strap for your project, one of the most critical factors to consider is the load capacity and strength required. According to a report from the Industrial Fabrics Association International, the tensile strength of webbing materials can vary significantly based on the type and construction, ranging from 2,000 to over 20,000 pounds. This wide range means that correctly evaluating the specific needs of your project is essential.

Additionally, the breaking strength of webbing straps, which is the maximum load that a strap can handle before failing, is typically tested under static conditions. For instance, a standard nylon webbing might have a breaking strength of around 5,000 pounds, while polyester alternatives might offer similar resilience but have better UV resistance. When determining the strength required, it’s vital to consider safety factors; industry standards often recommend a safety ratio of 3:1 for static loads, meaning a webbing strap rated for 5,000 pounds would be suitable for loads up to approximately 1,667 pounds. Understanding these principles is key to ensuring that the selected webbing strap meets the demands of your project while providing reliable performance and safety.

When it comes to selecting the best webbing strap for your project needs, material choice plays a critical role in ensuring both durability and weather resistance. According to the Industrial Fabrics Association International (IFAI), material selection can significantly impact the longevity and performance of webbing straps. For instance, polyester and nylon are two of the most popular options, each offering unique advantages in terms of strength and resistance to environmental factors. Polyester webbing is renowned for its minimal stretch and high UV resistance, making it ideal for outdoor applications where prolonged sun exposure is a concern. Research indicates that polyester can endure UV degradation significantly better than nylon, with studies showing a lifespan increase of up to 50% in harsh weather conditions.

On the other hand, nylon webbing boasts superior elasticity, which allows it to absorb shock loads effectively. This makes it an excellent choice for applications that require a flexible yet strong strap, such as climbing or rescue gear. However, nylon is more susceptible to UV damage; studies have demonstrated that nylon can lose up to 20% of its strength within a year of continuous exposure to sunlight. To mitigate this issue, manufacturers often treat nylon with UV inhibitors. Ultimately, understanding these material characteristics is essential for choosing the right webbing strap, ensuring it meets the demands of your specific project while providing the necessary durability and weather resistance.

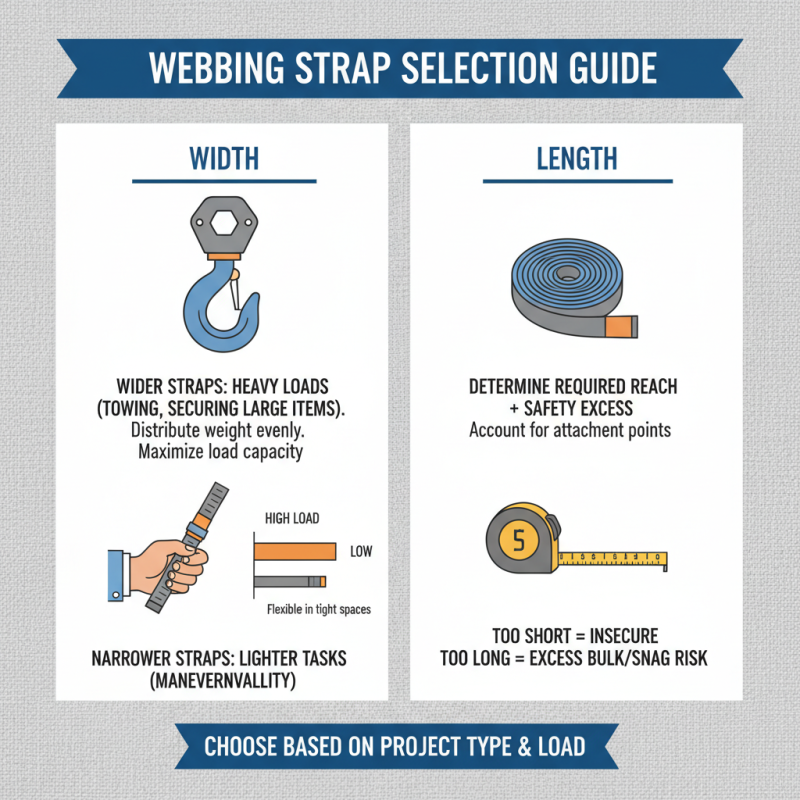

When selecting a webbing strap for your project, determining the appropriate width and length is crucial to ensure optimal performance and safety. The width of the strap significantly affects its load capacity and usability. Wider straps generally distribute weight more evenly and can handle heavier loads, making them suitable for heavy-duty applications such as towing or securing large items. Conversely, narrower straps are ideal for lighter tasks and provide better maneuverability in tight spaces. Before making a decision, assess the type of work you’ll be doing and choose a width that balances strength with flexibility.

Length is another vital factor in selecting a webbing strap. A strap that is too short may not provide the necessary reach for your project, leading to potential safety risks. On the other hand, using a strap that is excessively long can create complications, such as unnecessary bulk and difficulty in securing your load. To determine the right length, it helps to measure the distance between anchor points and consider any additional length required for knots or connections. Always err on the side of caution by opting for a bit more length to accommodate various setups while ensuring ease of use and safety.

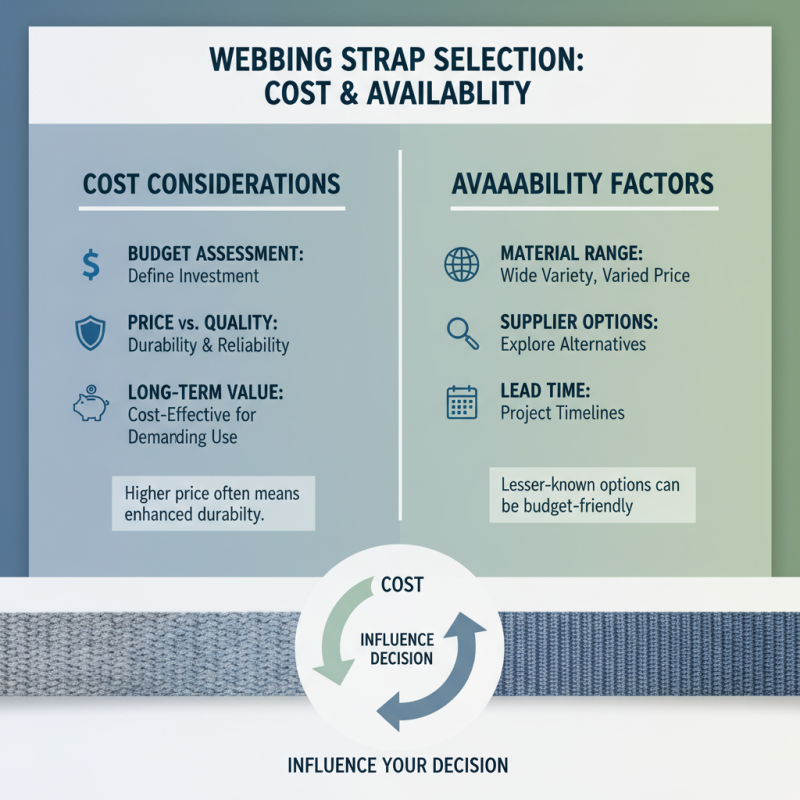

When selecting a webbing strap for your project, cost and availability are critical factors that can influence your decision. A wide range of materials and specifications is available, but these options can vary dramatically in price. It’s important to assess your budget and determine how much you are willing to invest in quality webbing. Often, higher-priced straps may feature enhanced durability and reliability, making them more cost-effective in the long run, especially for demanding applications. Conversely, if your project has budget constraints, exploring lesser-known materials or suppliers may yield suitable alternatives that meet your specific needs without breaking the bank.

Availability is another important consideration when choosing webbing straps. Some materials may be readily accessible in local hardware or specialty stores, while others may require online ordering or special shipping arrangements. Understanding the lead time for obtaining the straps can help you plan your project timeline effectively. It's wise to check various suppliers for stock levels and consider seasonal variations that might affect availability. Additionally, sourcing from multiple vendors can offer flexibility, allowing you to adapt your project needs if one supplier experiences delays or shortages. Balancing cost with reliable supply ensures that your project progresses smoothly and efficiently.