When embarking on a project that requires strength and durability, choosing the right material is crucial. One of the most reliable options in the market is Polyester Webbing, known for its impressive tensile strength and resistance to environmental factors. According to industry expert Michael Thompson, "Selecting the correct type of Polyester Webbing can be the difference between a successful project and a frustrating failure." This statement underscores the importance of understanding the specific requirements of your application and the characteristics of various webbing types before making a decision.

Polyester Webbing is widely used across various industries, from outdoor gear and automotive applications to securing loads and crafting accessories. Its versatility stems from its inherent qualities, such as UV resistance, minimal stretch, and excellent abrasion resistance. However, the process of choosing the right Polyester Webbing involves more than just strength; factors like width, weight capacity, and even color can play significant roles in the effectiveness of your project. As you delve into the selection process, keep in mind the specific demands of your application, and how different properties of Polyester Webbing can help meet those challenges effectively.

Polyester webbing is a versatile and durable material commonly used in various applications, from outdoor gear to automotive industries. One of its key properties is its high tensile strength, which allows it to withstand heavy loads without breaking or fraying. This makes polyester webbing an ideal choice for projects that require reliable support, such as in harnesses, slings, and straps. Additionally, polyester has excellent resistance to UV rays, preventing degradation from prolonged exposure to sunlight, which is crucial for outdoor applications.

Another important characteristic of polyester webbing is its resistance to moisture and mildew. Unlike some natural fibers, polyester does not absorb water easily, making it less susceptible to mold and rot. This quality ensures that the webbing maintains its integrity even in damp conditions, prolonging the lifespan of products made from it. Furthermore, polyester webbing is available in various widths, colors, and patterns, allowing for customization to suit specific project needs. Understanding these properties will enable you to make informed decisions when selecting the best polyester webbing for your tailored projects.

When selecting the best polyester webbing for your projects, understanding the load capacity is critical, as it directly impacts safety and performance. The tensile strength of polyester webbing can vary significantly, typically ranging from 1,000 to over 5,000 pounds, depending on its width, thickness, and weave pattern. A comprehensive industry report indicated that webbing with a higher tensile strength is essential for applications that bear heavy loads, such as outdoor gear or industrial equipment. Thus, before making a decision, it is vital to evaluate the specifications of the webbing, ensuring it meets or exceeds the required strength for your specific use case.

To accurately determine your strength requirements, consider both the static and dynamic loads your project will encounter. Static loads remain constant, while dynamic loads can fluctuate, causing stress to the webbing. The American Society for Testing and Materials (ASTM) provides guidelines for evaluating these load conditions. Additionally, it is advisable to apply a safety factor, often recommended to be at least 1.5 times the anticipated maximum load. This buffer accounts for wear and tear over time, environmental factors, and accidental overloads, safeguarding against potential failures and ensuring longevity in your projects. Engaging with resources such as the Composite Fabricators Association can further enhance your understanding of load capacities and factors influencing the performance of polyester webbing.

| Webbing Type | Width (inches) | Breaking Strength (lbs) | Weight (lbs per 100 ft) | Typical Applications |

|---|---|---|---|---|

| Polyester Webbing A | 1 | 1200 | 3.5 | Safety Harnesses, Straps |

| Polyester Webbing B | 1.5 | 3000 | 5.0 | Heavy-Duty Restraint |

| Polyester Webbing C | 2 | 4500 | 8.0 | Cargo and Lifting |

| Polyester Webbing D | 1.75 | 2100 | 4.0 | Outdoor and Camping |

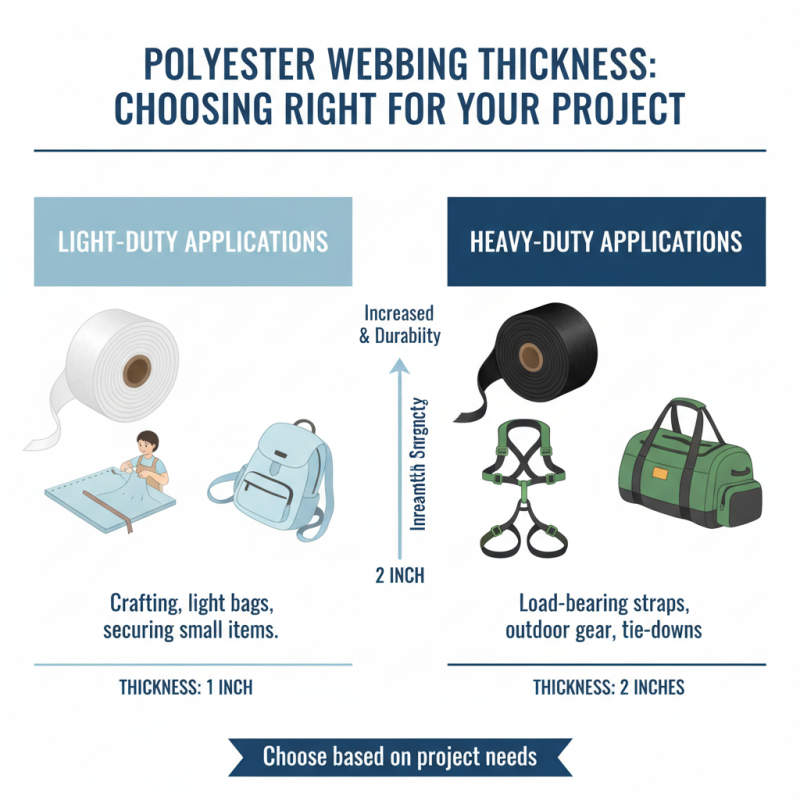

Choosing the right thickness of polyester webbing is crucial for ensuring the durability and functionality of your projects. Industry standards typically categorize webbing thickness from 1 inch to 2 inches; however, the ideal thickness often depends on the specific application. For instance, lighter applications such as crafting or securing lightweight items may only require a thinner webbing, while heavier applications, including load-bearing straps or outdoor gear, necessitate a thicker material to ensure strength and reliability.

When selecting the appropriate thickness, consider the load requirements and the conditions the webbing will face. Thicker webbing generally offers increased tensile strength, making it suitable for heavy-duty tasks. However, it might also add unwanted weight and bulk to your project. Understanding the environment—whether it’s exposure to UV rays, moisture, or abrasion—is equally important, as these factors can affect the longevity of the webbing. Ultimately, balancing thickness with functionality ensures that your chosen polyester webbing meets both the demands of your project and standards for safety.

When selecting polyester webbing for projects, understanding UV resistance and durability is crucial for ensuring long-term performance. Polyester's inherent properties offer excellent resistance to UV light, which is vital for applications exposed to sunlight. Over time, UV rays can degrade materials, causing weakening and color fading. High-quality polyester webbing is treated with additives that enhance its UV resilience, making it suitable for outdoor use. This feature is particularly important for items like straps, slings, and hitches that are likely to be exposed to direct sunlight for extended periods.

Additionally, durability is a key factor in choosing the right polyester webbing. The material should withstand not only UV exposure but also the stresses of varying environmental conditions, including moisture, temperature fluctuations, and abrasion. Polyester webbing boasts a strong resistance to water and mildew, making it ideal for marine applications or areas with high humidity. The combined benefits of UV resistance and durability ensure that the webbing maintains its integrity and functionality, providing reliability for various projects, whether in outdoor settings or demanding industrial environments. By carefully considering these factors, you can select the best polyester webbing that meets the longevity and performance requirements of your specific needs.

When selecting the best polyester webbing for specific projects, it's essential to consider the variety of applications where this versatile material excels. Polyester webbing is widely used in outdoor gear, automotive applications, and industrial settings due to its high strength, durability, and resistance to UV rays and moisture. Each of these applications tends to have unique requirements. For instance, when working on outdoor equipment such as hammocks or climbing gear, the webbing must not only be strong enough to support weight but also durable against the elements. Users should look for webbing that meets the required safety standards while providing the necessary resistance to wear and tear.

In contrast, projects in the automotive industry might prioritize webbing that can withstand higher temperatures or the exposure to oils and chemicals. This application may involve securing parts, creating straps, or other uses where flexibility and resilience are critical. Identifying these specific needs helps to narrow down the options and select a type of polyester webbing that provides optimal performance. Evaluating factors like tensile strength, width, and any additional coatings or treatments can further aid in making an informed choice tailored to the demands of the project at hand.