Choosing the right polyester webbing for your project needs is crucial for ensuring durability, safety, and functionality in various applications, from outdoor gear to industrial use. According to industry expert Dr. Martin Reynolds, a well-respected authority in textile engineering, "Selecting the appropriate polyester webbing is essential for optimizing performance and longevity in any project." This statement underscores the importance of careful consideration and understanding of the diverse options available in the polyester webbing market.

In this article, we will explore the key factors to consider when selecting polyester webbing for your specific requirements. We will delve into the properties of polyester, including its strength, resistance to UV rays, and abrasion, which are vital for making informed decisions. With the right guidance, you can ensure that your choice of polyester webbing enhances the performance and safety of your projects, whether for personal use or commercial applications. As we navigate through various considerations, it becomes clear that understanding the nuances of polyester webbing can significantly impact the success of your endeavors.

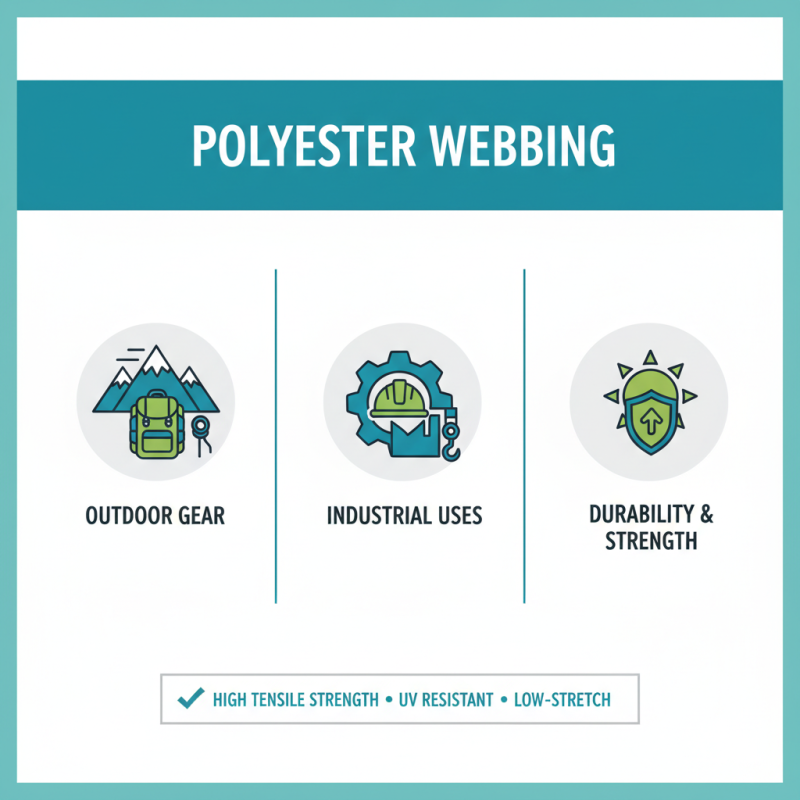

Polyester webbing is a versatile material often used in various applications ranging from outdoor gear to industrial uses. Its unique properties, such as high tensile strength, excellent resistance to UV light, and minimal stretch, make it ideal for both heavy-duty and lightweight projects. Understanding these characteristics is crucial when selecting the right type of polyester webbing for your specific needs. Whether you're making a backpack, safety harness, or cargo straps, knowing the weight capacity and environmental conditions can greatly influence your decision.

In addition to strength and durability, polyester webbing is appreciated for its resistance to abrasion and moisture. This makes it suitable for outdoor activities where exposure to the elements is a concern. There are various widths and thicknesses available, allowing for customization based on the project requirements. Whether you need a thicker webbing for heavy-duty tasks or a thinner variety for lighter applications, polyester webbing provides a reliable solution. Understanding these basics will enable you to select the most suitable webbing for your project, ensuring safety and efficiency in its application.

When selecting the right polyester webbing for your project, identifying your specific requirements is paramount. Polyester webbing is known for its strength, durability, and resistance to environmental factors. According to a report by the American Society for Testing and Materials (ASTM), the tensile strength of polyester webbing can range from 1,500 to 4,000 pounds, depending on its width and weave pattern. Consequently, understanding the load-bearing capacity needed for your project is essential. If you're working on applications that will undergo high tension or load, opting for webbing with higher tensile strength ratings is crucial.

Another critical factor to consider is the intended application of the webbing. Whether it’s used for outdoor gear, lifting equipment, or pet harnesses, different applications might require unique attributes. For example, webbing intended for outdoor use should prioritize UV resistance and water repellent qualities, as exposure to harsh conditions could lead to deterioration. A survey conducted by the Industrial Fabrics Association International (IFAI) reported that 63% of professionals in the industry consider environmental conditions as a deciding factor in their webbing selection. By clarifying the specific demands of your project and factoring in your local environmental conditions, you can make an informed choice that ensures the longevity and performance of the polyester webbing in your applications.

| Project Type | Load Capacity (lbs) | Width (inches) | Color Options | UV Resistance |

|---|---|---|---|---|

| Camping Gear | 500 | 1 | Green, Blue, Orange | Yes |

| Industrial Applications | 1000 | 2 | Black, Yellow | Yes |

| Safety Harness | 600 | 1.5 | Red, Orange | Yes |

| Belt Straps | 400 | 1 | Various | Yes |

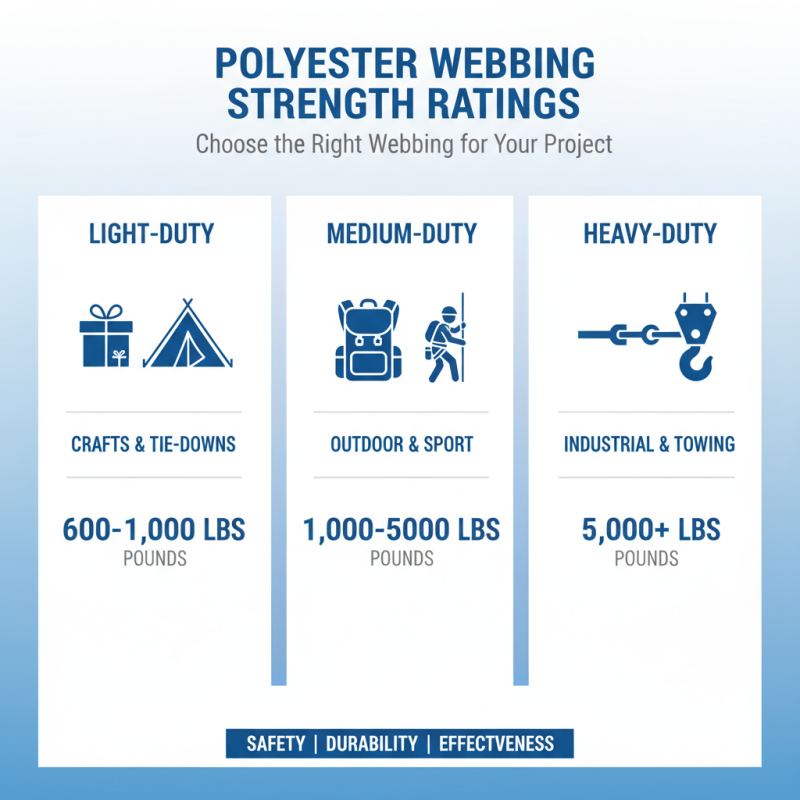

When selecting polyester webbing for your project, understanding the various strength ratings is crucial. Polyester webbing comes in different strengths, often measured in pounds or kilograms. These ratings indicate the maximum weight the webbing can safely handle before it risks breaking. For instance, light-duty webbing, suitable for crafts or simple tie-downs, may have a strength rating of around 600-1,000 pounds, while heavy-duty options can exceed 5,000 pounds. Evaluating these ratings helps ensure the safety and effectiveness of your project.

Tips: When checking strength ratings, consider not only the weight capacity but also the application. For example, if the webbing will endure dynamic loads, such as in lifting or securing cargo during transportation, opt for webbing with a higher strength rating. Additionally, check if the webbing's strength rating includes a safety factor. A safety factor of 5:1 is common for webbing applications, meaning the break strength is five times the working load limit.

To make an informed choice, assess the environment where the webbing will be used—factors like UV exposure, moisture, and abrasion can affect performance. Choosing the right polyester webbing tailored to your specific project requirements will ensure durability and longevity while maintaining safety standards.

When selecting polyester webbing for your project, determining the appropriate width and thickness is crucial to ensure functionality and durability. Industry standards suggest that the width of webbing can significantly affect its strength and usability. Typically, webbing widths range from 1 inch to over 4 inches, with wider options often utilized in heavy-duty applications, such as towing or lifting. A report by the Textile Research Journal indicates that wider webbing can distribute load more evenly, which minimizes concentrated stress points that could lead to failure.

Thickness, measured in millimeters or inches, also plays a vital role in the webbing's overall strength and performance. According to data from the American Society for Testing and Materials (ASTM), thicker webbing generally provides enhanced load-bearing capabilities, making it suitable for applications where safety is paramount. For instance, a webbing with a thickness of 0.1 inches might support a load of up to 1,500 pounds, whereas a thickness of 0.2 inches can support significantly more, depending on the specific weave and material quality.

It is essential to consider both the weight of the items being secured and the operating conditions, such as exposure to UV rays or moisture, when deciding on the width and thickness. Choosing the right specifications not only ensures the effectiveness of the project but also contributes to the longevity of the materials used, reducing replacement costs over time.

When selecting polyester webbing for various projects, it's essential to consider additional features and treatments that can significantly enhance performance. Various treatments can improve webbing's resistance to UV degradation, moisture absorption, and abrasion. According to a report by the Industrial Fabrics Association International, polyester webbing that is treated with UV inhibitors can increase exposure longevity by up to 50% compared to untreated alternatives. This treatment is crucial for applications such as outdoor gear, where the webbing is regularly exposed to harsh sunlight.

Furthermore, many polyesters can benefit from specialized coatings that enhance water resistance or reduce friction during use. For example, water-repellent treatments can repel moisture, thereby reducing the risk of mildew and rot in applications where webbing might encounter wet conditions. A study conducted by the American Society for Testing and Materials (ASTM) indicates that treated polyester webbing can maintain its tensile strength and integrity even in conditions of high humidity, making it ideal for marine applications. By understanding and utilizing these additional features, designers and engineers can select the right polyester webbing tailored to their specific project needs, ensuring both durability and functionality.