Choosing the right webbing sling for your lifting needs is essential for ensuring safety and efficiency in any lifting operation. Webbing slings are versatile lifting tools made from high-strength synthetic materials, designed to provide improved handling and reduced weight compared to traditional lifting slings. As various industries continue to embrace innovative lifting solutions, understanding the characteristics and applications of webbing slings becomes increasingly important.

In this guide, we will explore the different factors to consider when selecting a webbing sling, such as material type, load capacity, length, and safety features. Each of these elements can significantly impact the performance of the sling in specific lifting scenarios. Additionally, we will discuss best practices to ensure that you are making informed decisions that align with both safety standards and operational requirements. Whether you're in construction, manufacturing, or any other field that involves lifting heavy loads, having the right webbing sling can make all the difference in achieving reliable results without compromising safety.

When it comes to lifting applications, choosing the right webbing sling is crucial for safety and efficiency. There are several types of webbing slings available, each designed to handle different loads and lifting conditions. The most commonly used are flat slings, round slings, and endless slings.

Flat slings offer a wide surface area, which helps distribute the load evenly, making them suitable for lifting heavy and bulky items. They are ideal for construction and industrial environments where the load shape varies.

Round slings, made from a soft and flexible material, are another excellent option. They conform to the shape of the load, providing a secure grip and less risk of slippage. This type is particularly useful for delicate or irregularly shaped items.

Endless slings, on the other hand, have no defined ends, allowing for versatile configurations and the ability to lift from multiple angles. Understanding the specific requirements of your lifting task can help you select the most appropriate type of webbing sling, considering factors such as load weight, shape, and the environment in which the lifting occurs.

When selecting the right webbing sling for your lifting needs, it is crucial to consider several key factors. One of the most important is the sling's capacity—this is typically determined by the type of lifting and the weight of the load. According to the Occupational Safety and Health Administration (OSHA), the working load limit (WLL) should never exceed the sling's rated capacity, which varies between different materials and designs. Polyester webbing slings, for example, are known for their high strength-to-weight ratio and excellent resistance to abrasion, making them ideal for lifting tasks requiring both robustness and lightweight handling.

Another critical factor is the environmental conditions in which the sling will be used. Exposure to chemicals, extreme temperatures, or moisture can affect the integrity of the webbing material. A report by the National Institute for Occupational Safety and Health (NIOSH) emphasizes that slings used in outdoor environments should be chosen carefully, as UV exposure can degrade synthetic materials over time. Additionally, understanding the type of hitch you will use (choke, vertical, or basket) will also influence your selection, as each hitch type affects the sling's effectiveness and load capacity. Thus, comprehensive knowledge of both the sling specifications and the operational environment is essential for ensuring safety and efficiency in lifting operations.

| Factor | Description | Recommended Use | Safety Considerations |

|---|---|---|---|

| Material | Choose between nylon and polyester based on the environment. | Outdoor use: Polyester; Indoor use: Nylon | Ensure material compatibility with chemicals and sunlight. |

| Load Capacity | Check the maximum load the sling can safely lift. | Heavy lifting tasks requiring high capacity. | Do not exceed the rated capacity to prevent accidents. |

| Length | Choose the correct length to ensure proper lifting angles. | When lifting tall items or needing to increase distance. | Longer slings can cause more swing; account for space. |

| Type | Flat, round, or endless slings offer different advantages. | Flat slings for lifting flat loads; round slings for irregular shapes. | Select the type based on load shape and surface safety. |

| Certification | Ensure the sling meets industry safety standards. | Use certified slings for compliance in workplaces. | Always check for valid certification tags before use. |

When selecting a webbing sling for lifting operations, adherence to safety standards and regulations is paramount. In many regions, regulatory bodies set stringent guidelines to ensure that webbing slings meet specific safety requirements. These regulations often include specifications on materials, design, and testing methods to guarantee that slings can safely support the intended loads without risk of failure. Familiarity with standards such as those from the American National Standards Institute (ANSI) or the Occupational Safety and Health Administration (OSHA) helps users choose appropriate slings that comply with legal and safety expectations.

In addition to understanding these regulations, operators should also be aware of the importance of load capacity ratings and inspection protocols. Webbing slings are classified by their load-bearing capacities, and users must ensure that the sling selected is appropriate for the weight and nature of the load being lifted. Regular inspections for wear, fraying, or damage are essential to maintaining safety and prolonging the life of the slings. Following these safety standards not only minimizes risks but also promotes a culture of safety within industries reliant on lifting equipment.

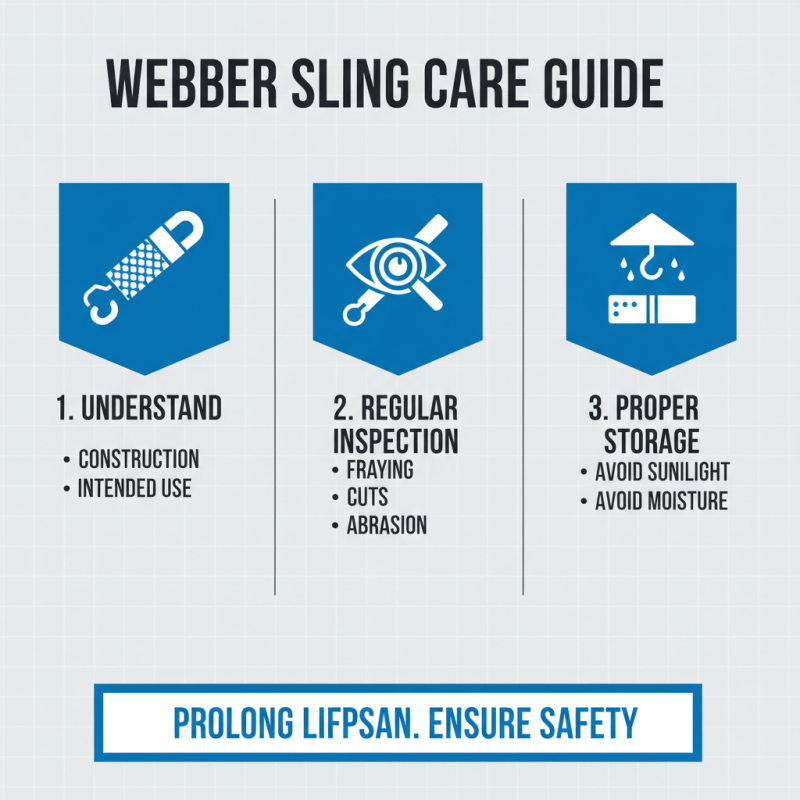

When it comes to maintaining and caring for webbing slings, understanding their construction and intended use is vital for prolonging their lifespan. Webbing slings are commonly used in lifting applications, and neglecting their maintenance can lead to wear and tear, compromising safety. Regular inspections of the slings for any signs of fraying, cuts, or abrasion are essential to ensure they remain in usable condition. It's also important to store slings properly, as exposure to harsh conditions such as sunlight and moisture can degrade the material over time.

In addition to regular inspections, cleaning your webbing slings is a crucial aspect of their care. Depending on the material, slings can often be washed with mild detergents and warm water, followed by thorough rinsing and air drying. Avoid using harsh chemicals or exposing the slings to extreme temperatures, as these can negatively affect the fibers. Implementing these maintenance practices not only enhances the durability of your webbing slings but also ensures safety and reliability in lifting operations, making it essential for any handler or equipment manager to integrate them into their routine.

When selecting webbing slings for lifting applications, it’s crucial to avoid common mistakes that can lead to unsafe lifting practices. One of the primary errors is underestimating the importance of load capacity. According to industry reports, choosing a sling with a load capacity that is too low for the intended lift increases the risk of sling failure. In fact, incorrect use of soft slings can cause sudden failures, even when the load being lifted is below the sling’s rated capacity. Proper identification of load weight and understanding the sling’s limitations are essential steps in ensuring safety.

Another frequent mistake is neglecting to consider the lifting environment. Factors such as the presence of sharp edges, temperature variations, and exposure to chemicals can greatly affect the performance of webbing slings. Many users overlook these environmental conditions, which can lead to a significant decrease in the sling's lifespan or performance. Data indicates that slings subjected to harsh conditions can fail prematurely, underlining the need for selecting materials that are suitable for specific lifting scenarios. Attending events like LiftEx 2024 will provide valuable insights and innovations on lifting safety and efficiency, allowing users to better understand how to choose the right webbing slings for their needs.