Selecting the right Webbing Sling can seem daunting. With a variety of types and strengths available, making the correct choice matters. The right sling is crucial for safety and efficiency in lifting applications.

When considering a Webbing Sling, understanding your specific needs is vital. Think about the load size and weight. Each sling type has unique characteristics. Some are better for heavy objects, while others excel in delicate tasks.

It’s easy to overlook critical details. For instance, some users may focus solely on price rather than quality. Ignoring the environment where the sling will be used can lead to serious mistakes. Choosing a Webbing Sling requires careful consideration to avoid potential hazards and ensure successful lifting.

Webbing slings come in various types and materials, each suited for specific applications. Understanding these differences can significantly impact your choice. Common materials include nylon, polyester, and polypropylene. Nylon offers high elasticity and strength, making it ideal for heavy loads. Polyester, on the other hand, is more UV resistant and has less stretch, which can be beneficial in outdoor settings. Polypropylene is lighter and often used for lighter tasks.

Different types of webbing slings also play a crucial role. Flat slings are versatile and can be used in various configurations. Round slings provide a soft and flexible option, perfect for delicate surfaces. Sling colors often indicate their load ratings, which can lead to confusion. Misreading these can result in unsafe lifting practices.

When selecting a webbing sling, consider your specific needs. Assess the load type and lifting conditions. Reflecting on these factors can guide you in making a better choice. Avoid overthinking the decision, but ensure you understand the basics. Sometimes, the simplest solution is the most effective. Always err on the side of caution, as safety should be your foremost priority.

This chart compares various types of webbing slings based on their break strength, measured in kilonewtons (kN). Polyester, Nylon, Kevlar, and Polypropylene are commonly used materials, each with distinct strength characteristics suitable for different applications.

When selecting a webbing sling, assessing load capacity is crucial. Each sling has a specific load limit, detailed in its specifications. Understanding this limit is vital for safety. Overloading a sling can lead to accidents. It's essential to check the weight of your load before choosing a sling.

Safety factors should not be overlooked. They provide a buffer for regular use and unforeseen circumstances. A sling rated with a higher safety factor can handle more stress. However, it must be compatible with the material's strength. Choosing the wrong one can compromise safety.

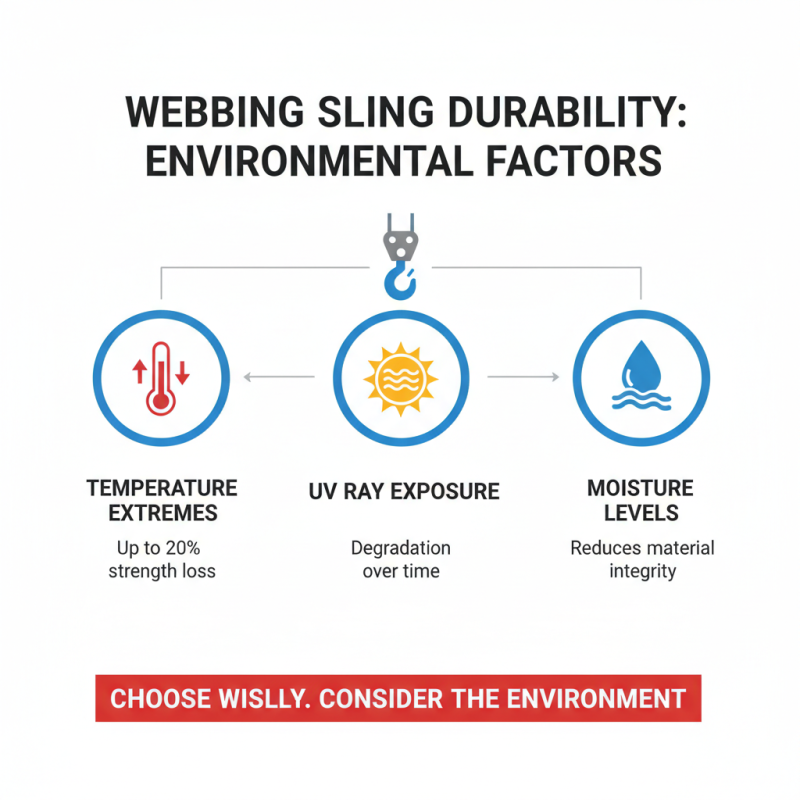

It's also important to consider environmental factors. Factors like moisture and temperature can affect the sling's performance. You might think a sling is safe, but the conditions can change that. Reflecting on these aspects is essential for making an informed choice.

| Sling Type | Load Capacity (lbs) | Safety Factor | Material | Usage |

|---|---|---|---|---|

| Nylon Webbing Sling | 6,600 | 5:1 | Nylon | General Purpose |

| Polyester Webbing Sling | 9,200 | 7:1 | Polyester | Heavy Lifting |

| Chain Sling | 13,200 | 4:1 | Steel | Construction |

| Wire Rope Sling | 20,000 | 5:1 | Steel | Heavy-Duty |

| Round Sling | 8,800 | 7:1 | Polyester | Lifting Thin Loads |

When selecting a webbing sling, evaluating environmental conditions is crucial for optimal performance. Temperature, exposure to UV rays, and moisture levels can significantly affect sling durability. For instance, studies show that webbing slings can lose up to 20% of their strength when exposed to extreme temperatures. This information highlights the importance of considering the environment in your choice.

Tips: Always assess the working conditions before purchasing a sling. This foresight can prevent potential hazards and failures.

Furthermore, different materials behave differently in varied environments. For example, nylon slings are stronger in wet conditions but may degrade faster under UV exposure. In contrast, polyester slings offer better UV resistance but may not perform as well in moisture. A recent report indicated that nearly 30% of sling failures occur due to improper material selection based on environmental factors. It’s vital to weigh these factors carefully.

Tips: Consult with an industry professional to ensure proper material selection. Their expertise can guide you toward a safer choice.

Selecting the right sling length and width is crucial for safety and efficiency in lifting operations. The sling's length should accommodate the load size and lifting height. A sling that is too short can create a risk of load swing. Conversely, a sling that is too long may lead to instability. According to a recent industry report, slings 10-20% longer than the minimum required length yield safer handling.

Width is equally important. A wider sling distributes the load more evenly, reducing pressure points that might weaken the sling. For example, a 4-inch wide sling can support up to 30% more weight compared to a 2-inch wide option in some tests. However, width should suit the task. A sling that is excessively wide is unnecessary and can hinder maneuverability.

Consider also the lifting environment. In confined spaces, a wider, longer sling may be more cumbersome. You might need a balance between maneuverability and safety. Therefore, evaluating your specific needs and potential challenges is vital. The data shows that 30% of accidents occur due to improper sling selection. Reflecting on these aspects can lead to better decisions.

When choosing a webbing sling, maintenance is key for longevity and safety. Regular checks can prevent accidents. Always inspect your sling for visible damage, like fraying or wear. If you see issues, replace it immediately.

Proper cleaning is essential. Use mild soap and water for washing. Avoid harsh chemicals that might degrade the material. Once cleaned, ensure the sling dries completely before storage. This step is often overlooked, yet moisture can weaken the fibers.

Storing your sling correctly can extend its life. Keep it in a cool, dry place, away from direct sunlight. If you often use your sling outdoors, consider protecting it from elements. Even small actions, like avoiding sharp edges during use, can make a big difference. Reflecting on these habits can enhance safety during operation.