Ratchet straps are essential tools widely utilized in various industries for secure load fastening and transportation. According to a report by Research and Markets, the global cargo securing market is projected to grow significantly, driven by the increasing demand for safety and efficiency in logistics and transportation. These straps provide a reliable solution for securing heavy loads during transit, minimizing the risk of damage and ensuring compliance with safety regulations.

When selecting the right ratchet strap, it is crucial to consider factors such as load capacity, strap material, and length. A recent industry analysis indicates that improper use or inadequate selection of ratchet straps can result in accidents and losses, highlighting the importance of making informed choices. The proper tension and attachment of ratchet straps can enhance load stability significantly, reducing the likelihood of cargo shifting or falling during transportation.

As the logistics industry continues to evolve, understanding how to choose the right ratchet straps for specific needs becomes increasingly vital. Thorough knowledge of their application and features not only improves operational efficiency but also ensures safety standards are met, reinforcing the necessity of investing in high-quality securing solutions.

Ratchet straps are essential tools used for securing loads during transportation. Their design features a ratchet mechanism that allows users to tighten the strap around the cargo, creating a secure hold that minimizes the risk of shifting or falling during movement. These straps are highly effective for a variety of applications, from securing furniture in a moving truck to holding equipment in place on a trailer. The versatility of ratchet straps makes them a popular choice for both personal and commercial use, ensuring that items remain safe and secure while on the road.

When selecting the right ratchet strap for your needs, it is crucial to consider several factors. First, think about the weight and size of the load you intend to secure, as this will dictate the strap's working load limit (WLL) and width. Additionally, the material of the strap plays a significant role in durability and weather resistance. For instance, polyester is commonly used for its strength and ability to resist UV damage. Finally, consider the length of the strap to ensure it accommodates your cargo effectively. By carefully assessing these criteria, you can choose a ratchet strap that provides the necessary security for your specific load.

| Feature | Description | Use Case |

|---|---|---|

| Material | High-strength polyester webbing is common for durability. | Ideal for heavy loads such as construction materials. |

| Width | Common widths range from 1 inch to 4 inches. | Choose wider straps for larger loads requiring more surface area. |

| Breaking Strength | Rated based on the maximum load they can securely hold. | Essential for transporting valuable equipment safely. |

| Length | Available in various lengths, typically between 10 to 30 feet. | Longer lengths are useful for securing larger or bundled items. |

| End Fittings | Options include S-hooks, D-rings, or flat hooks for attachment. | Select based on the anchoring points available on your load. |

| Ratchet Mechanism | Allows for easy tightening and adjustment of the strap. | Useful when a firm hold on the load is critical. |

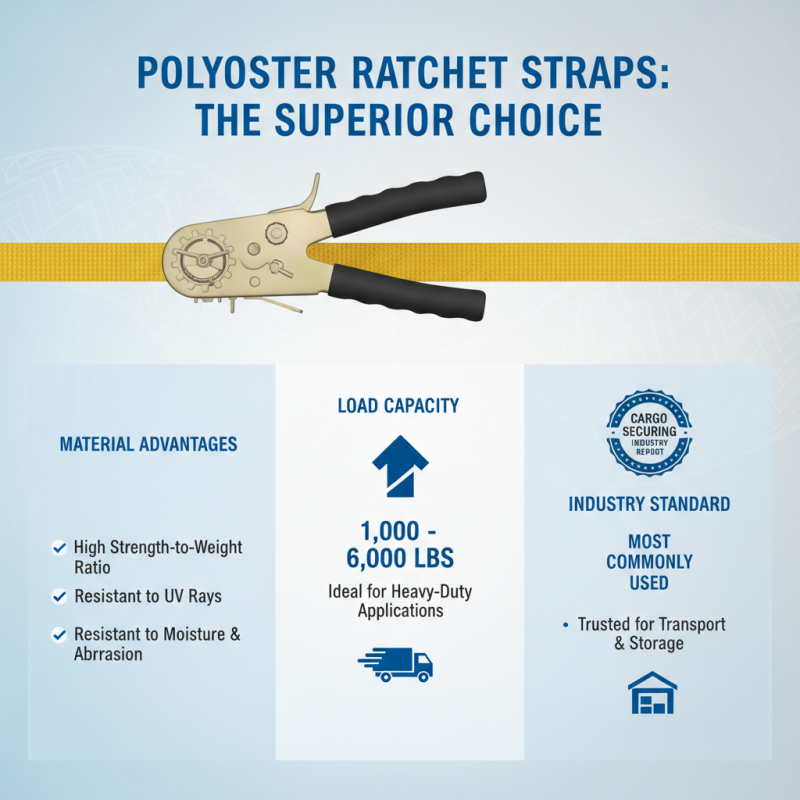

When it comes to selecting the right ratchet strap for your needs, understanding the various types based on material and design is crucial. Ratchet straps primarily come in two materials: polyester and nylon. Polyester is the most commonly used material in the industry due to its high strength-to-weight ratio and resistance to UV rays, moisture, and abrasion. According to a report by the Cargo Securing Industry, polyester ratchet straps can typically handle loads ranging from 1,000 to 6,000 pounds, making them ideal for heavy-duty applications in transport and storage.

On the other hand, nylon ratchet straps are known for their elasticity and durability. They are often preferred for securing materials that require a bit of give, as nylon can stretch under load without breaking. However, they are less resistant to UV light and moisture, which makes them more suited for indoor use or applications where environmental conditions are controlled. The International Organization for Standardization (ISO) suggests that when calculating the load capacity of ratchet straps, one should take into account factors such as the working load limit (WLL) and the break strength, ensuring that the selected strap matches the specific demands of the cargo being secured.

In terms of design, ratchet straps can feature different hooks (like S-hooks, flat hooks, or L-hooks) and various buckle styles, impacting their usability and load distribution. For example, a ratchet strap with a flat hook is better suited for flatbeds, as it provides a secure connection without excess protrusions. Choosing the right combination of material and design ensures not only the safety of the cargo but also enhances the efficiency of the loading and unloading process, a critical aspect in the logistics and transportation sector where time is often of the essence.

When choosing ratchet straps, determining the correct load capacity is essential for ensuring safety and efficiency. Load capacity refers to the maximum weight that a ratchet strap can securely hold during transportation or storage. It is typically expressed in terms of working load limit (WLL), which indicates the safe limit under normal usage conditions. To identify the required load capacity, start by assessing the total weight of the items you plan to secure. It is important to consider the heaviest item in your load, as the total weight will dictate the strength needed in your ratchet straps.

Once you have established the total weight, multiply this figure by a safety factor, generally ranging from 1.5 to 2. This precaution accounts for potential stressors such as movement during transport, uneven weight distribution, or environmental factors that could affect the performance of the straps. After determining the load capacity needed, select ratchet straps that meet or exceed this requirement. Additionally, be mindful of the strap width, material, and hook type, as these factors also impact the overall strength and reliability of the straps in securing your load effectively.

When selecting the right ratchet strap for your needs, key features such as hooks, ratchets, and strap width should be carefully considered. First, the type of hooks is crucial as they determine how the strap attaches to your cargo or anchor points. Common hook styles include S-hooks, J-hooks, and flat hooks. Each type serves different purposes and offers varying levels of security. S-hooks are often used for lighter loads, while flat hooks provide a more secure grip for heavier items, ensuring that your cargo remains in place during transit.

Next, the ratchet mechanism itself plays a significant role in the effectiveness of the strap. A high-quality ratchet allows for easy tightening and secure holding of the load. Look for a ratchet with a solid build, as this will not only facilitate smooth operation but also enhance the durability of the strap. Additionally, the strap width is another important factor; wider straps usually distribute weight more evenly and reduce the chance of damage to the cargo. However, make sure the width aligns with the load being secured, as excessively wide straps can be unnecessarily bulky, while too narrow straps may not offer sufficient strength for heavier cargo.

When using ratchet straps, proper application is crucial to ensure safety and effectiveness. First, always inspect the strap for any signs of wear or damage before use. A frayed or worn strap can lead to failure under tension, posing a risk to both the load and individuals nearby. Additionally, ensure that the strap is appropriately rated for the weight it is intended to secure. Overloading a strap can cause it to snap, potentially resulting in injury or damage.

Proper usage also includes securing the load correctly. When tightening the strap, make sure it is evenly distributed across the load without crossing over itself, as this can lead to uneven tension and increased risk of slippage. Always release the tension gradually and avoid using your body to apply force, as sudden releases can cause the strap to recoil. When storing ratchet straps, keep them clean, dry, and free from excess tension to prolong their life and maintain their integrity for future use.