HOW to CHOOSE the RIGHT webbing sling?

Choosing the right Webbing Sling is crucial for safety and efficiency in lifting operations. Here’s a comprehensive guide to help you make the right selection:

1. Determine the Working Load Limit (WLL):

The Most Important Factor: This is the maximum weight the sling is designed to lift safely. Never exceed the WLL.

Calculate the Load Weight: Accurately determine the weight of the load you’ll be lifting. If unsure, it’s always better to overestimate.

Consider the Sling Angle: The angle between the sling legs significantly affects the load on each leg. As the angle increases, the load on each leg increases. Use a sling angle chart or calculator to determine the increased load. A good practice is to keep sling angles below 60 degrees. The smaller the angle, the greater the lifting capacity.

Apply a Safety Factor: Reputable manufacturers incorporate a safety factor (typically 5:1) into the WLL. However, it’s crucial to understand and account for this factor yourself.

2. Choose the Right Sling Configuration:

Vertical Hitch: The simplest configuration, where the sling supports the load directly from above. WLL = Sling’s WLL

Choker Hitch: The sling is passed around the load and then choked back onto itself. WLL is reduced (usually to 75% or 80% of the vertical hitch WLL). This configuration is less stable than a vertical hitch and can damage the sling if improperly used. Only use choke hitches designed for webbing slings.

Basket Hitch: The sling cradles the load from below, with both ends attached to the lifting hook. WLL is doubled (compared to the vertical hitch WLL), if the angle between the legs is 90 degrees or less.

Bridle Hitch: Uses multiple legs to distribute the load. The WLL depends on the number of legs and the angle between them. Use a sling angle chart or calculator to determine the WLL.

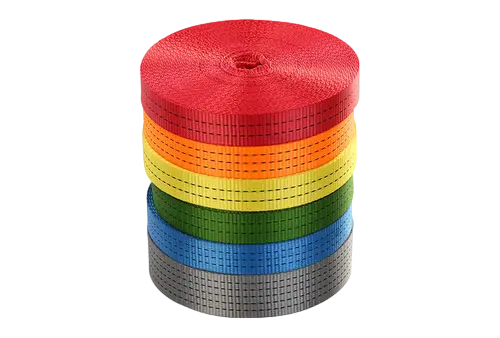

3. Select the Appropriate Sling Material:

Polyester: Most common. Offers good strength, resistance to UV degradation, and is relatively inexpensive. Not suitable for acidic environments.

Nylon: Stronger than polyester and stretches more, which can be beneficial for shock absorption. Susceptible to degradation from sunlight and acidic conditions.

4. Consider the Working Environment:

Temperature: Extreme temperatures can affect the strength of Synthetic Slings. Check the manufacturer’s specifications for temperature limits.

Chemical Exposure: Certain chemicals can degrade synthetic fibers. Select a sling material that is resistant to the chemicals present in the work environment. Polyester is not suitable for acidic environments, and nylon is not ideal for alkaline conditions.

Abrasive Surfaces: If the sling will be used in contact with abrasive surfaces, choose a sling with a durable protective cover or use edge protectors.

Outdoor Use: If the sling will be exposed to sunlight, choose a material with good UV resistance (such as polyester).

5. Choose the Right Sling Type:

Eye-and-Eye (Endless) Sling (also called Round Sling): Versatile and can be used in all hitch types. The endless design allows the wear point to be rotated, extending the sling’s lifespan.

Flat Eye-and-Eye Sling: The eyes are flattened and reinforced.

Twisted Eye-and-Eye Sling: The eyes are twisted to allow for better alignment with the load.

Reversed Eye Sling (also called Wide Body Sling): Wider body for better load distribution and stability.

6. Sling Length:

Calculate the Required Length: Consider the size and shape of the load, as well as the lifting height.

Avoid Excessive Length: Using a sling that is too long can create unnecessary slack and increase the risk of instability.

7. Check for Proper Labeling and Certification:

Legible Markings: The sling must be clearly marked with its WLL, sling type, material, manufacturer’s name, and other relevant information.

Certification: Ensure the sling is certified to meet relevant safety standards (e.g., ASME B30.9, EN 1492-1).

8. Regular Inspection:

Before Each Use: Inspect the sling for any signs of damage, such as cuts, tears, abrasions, chemical burns, or distorted fittings.

Remove Damaged Slings: Immediately remove any damaged slings from service and discard them properly.

Periodic Inspections: Conduct regular inspections by a qualified person to ensure the slings are in good working condition. Keep a record of all inspections.

Key Questions to Ask Yourself:

What is the weight of the load?

What is the shape and size of the load?

What type of hitch will I be using?

What is the sling angle?

What is the working environment like?

if you have any questions , please contact MEDEER, we will carefully consider all factors related, and help you choose the right webbing sling for your lifting needs and ensure a safe and efficient operation.